A403 WP321-S Return Bend Composition

| UNS Designation |

C |

Mn |

P |

S |

Si |

N |

Cr |

Mo |

| S32100 |

0.08 |

2 |

0.045 |

0.03 |

1 |

17.0–19.0 |

9.0–12.0 |

... |

A403 WP321-S Return Bend Strength

The A403 WP321 Return Bend is a pipe fitting made of WP321 stainless steel as specified in ASTM A403 standard and is mainly used for 180° steering in pipe systems. Here is a detailed explanation of its strength:

1. Characteristics:

High temperature oxidation and corrosion resistance.

Good mechanical properties and weldability.

The addition of titanium prevents the precipitation of chromium carbide and improves the resistance to intergranular corrosion.

2. Strength parameters:

The strength parameters of WP321 stainless steel usually include the following aspects:

Tensile Strength: ≥515 MPa (75,000 psi). Yield Strength: ≥205 MPa (30,000 psi). Elongation: ≥35% (within 50mm standard distance).

Hardness range: Usually HB ≤187 (Brinell hardness).

Voltage resistance:Working pressure: Determined according to piping design standards (such as ASME B16.9), usually suitable for medium and high pressure systems. Bursting pressure: much higher than working pressure, depending on wall thickness and diameter.

3. Strength influencing factors:

Wall thickness: The greater the wall thickness, the higher the strength.

Manufacturing process: The Return Bend strength of seamless manufacturing is higher than that of welded manufacturing.

Temperature: WP321 can still maintain high strength at high temperatures, but the strength reduction factor at specific temperatures should be referred to.

4. Application Scenarios:

High temperature environment: such as boilers, heat exchangers, steam pipelines.

Corrosive media: such as chemical industry, petrochemical industry.

Where resistance to intergranular corrosion is required: e.g. piping systems used after welding.

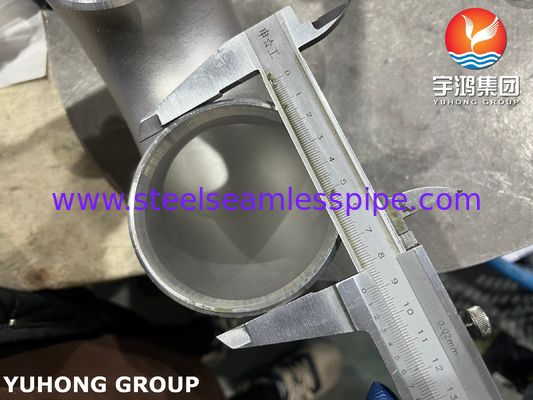

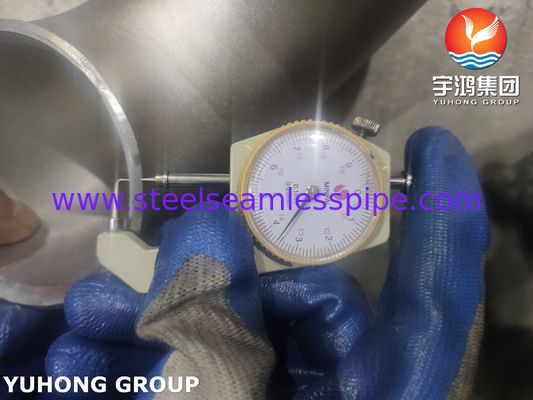

5. Strength verification:

Test standard: Strength test according to ASTM A403 and ASME B16.9.

Test items: Hydraulic test: verify the pressure performance.

Tensile test: Verify tensile strength and yield strength.

Hardness test: Verify whether the hardness of the material meets the standard.

6. Comparison with other materials:

Compared to carbon steel: Similar strength, but WP321 has better corrosion resistance and high temperature resistance.

Compared to 304 stainless steel: similar strength, but WP321 has better resistance to intergranular corrosion due to the titanium content.

Compared with 316 stainless steel: the strength is similar, but 316 has better pitting resistance because it contains molybdenum.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!